EM50R Handheld PU System

EM50R Handheld PU System - JIT Foam Packaging

Precision. Protection. Performance.

At Foam Packaging Solutions, we offer advanced manual foam packaging systems engineered for top-tier protection and performance. Our on-site foaming solutions deliver custom-fit cushioning for products of all shapes and sizes—right when and where you need it.

Ideal for businesses looking to reduce damage, save space, and cut costs, our system molds protective foam around your product with precision, creating strong, shock-absorbing support. It’s simple, efficient, and adaptable—perfect for both small batches and high-volume operations.

Protect smarter. Package better. Perform stronger—with Foam Packaging Solutions.

Key Advantages

Our foam forms around items of any shape or size, creating a custom-molded shell that offers maximum protection. Ideal for fragile, sensitive, or high-value products.

The foam expands up to 200 times its liquid size, reducing the need for bulky packaging materials. This saves storage space and significantly lowers shipping and material costs.

No need for complex machines—our manual system is easy to use, requires minimal setup, and is perfect for small to mid-scale operations needing flexibility.

With reusable molds and consistent foam output, you get dependable protection every time. Great for maintaining packaging quality across large or repeated shipments.

Smart Protection in Action

How It Works – Handheld Packaging

Step 1: Product Placement

Place the item to be packaged into the box or mold. Ensure it is centered and stable before proceeding. The packaging form must match the shape and size of the product for secure encasing.

🔹 What’s happening: This step shows careful alignment of the product before packing begins.

🔹 Purpose: Ensures the product is correctly positioned to avoid damage and maintain packaging quality.

Step 2: Sealing or Packing

Dispense the two-component foam mixture into the packaging space. The foam begins to expand immediately, conforming around the product. It is important to act quickly and distribute evenly.

🔹 What’s happening: The hand packer compresses or seals the foam around the product.

🔹 Purpose: Provides secure wrapping to protect the contents during handling and transport.

Step 3: Final Output

Allow the foam to fully expand and cure. This creates a custom-fit cushion around the item, ensuring excellent shock absorption and protection during transport.

🔹 What’s happening: The packaging is complete, and the product is safe for shipping or storage.

🔹 Purpose: Highlights the final, professionally packed result—clean, secure, and ready to go.

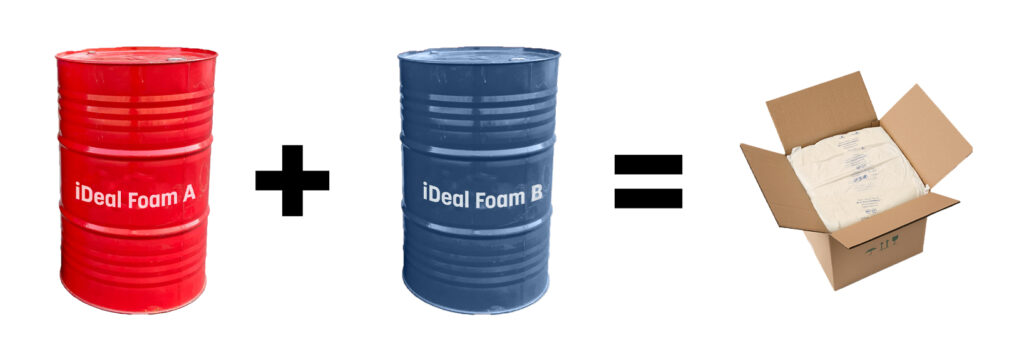

Two Components. One Smart Foam Solution.

Our PU foam is created by blending iDeal Foam A and iDeal Foam B, resulting in high-performance cushioning foam that molds perfectly around your product. This in-box foam solution offers superior protection, easy application, and a snug fit—making it ideal for shipping delicate, valuable, or irregularly shaped items.